ความรู้เกี่ยวกับ LED

A light-emitting diode (LED) is a semiconductor device that emits incoherent narrow-spectrum light when electrically biased in the forward direction. This effect is a form of electroluminescence. The color of the emitted light depends on the chemical composition of the semiconducting material used, and can be near-ultraviolet, visible or infrared.[1] Rubin Braunstein of the Radio Corporation of America first reported on infrared emission from GaAs and other semiconductor alloys in 1955.[2] Experimenters at Texas Instruments, Bob Biard and Gary Pittman, found in 1961 that gallium arsenide gave off infrared (invisible) light when electric current was applied. Biard and Pittman were able to establish the priority of their work and received the patent for the infrared light-emitting diode. Nick Holonyak Jr. of the General Electric Company developed the first practical visible-spectrum LED in 1962.[3]

Contents[hide] |

LED technology

Physical function

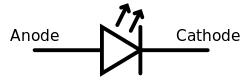

An LED is a special type of semiconductor diode. Like a normal diode, it consists of a chip of semiconducting material impregnated, or doped, with impurities to create a structure called a p-n junction. As in other diodes, current flows easily from the p-side, or anode to the n-side, or cathode, but not in the reverse direction. Charge-carriers - electrons and electron holes flow into the junction from electrodes with different voltages. When an electron meets a hole, it falls into a lower energy level, and releases energy in the form of a photon as it does so.

The wavelength of the light emitted (first documented by Scott Miles at the University of Minnesota in 1973), and therefore its color, depends on the band gap energy of the materials forming the p-n junction. In silicon or germanium diodes, the electrons and holes recombine by a non-radiative transition which produces no optical emission, because these are indirect bandgap materials. The materials used for an LED have a direct band gap with energies corresponding to near-infrared, visible or near-ultraviolet light.

LED development began with infrared and red devices made with gallium arsenide. Advances in materials science have made possible the production of devices with ever-shorter wavelengths, producing light in a variety of colors.

LEDs are usually built on a n-type substrate, with electrode attached to the p-type layer deposited on its surface. P-type substrates, while less common, occur as well. Many commercial LEDs, especially GaN/InGaN, also use sapphire substrate. Substrates that are transparent to the emitted wavelength, and backed by a reflective layer, increase the LED efficiency. The refractive index of the package material should match the index of the semiconductor, otherwise the produced light gets partially reflected back into the semiconductor, where it gets absorbed and turns into additional heat.

Conventional LEDs are made from a variety of inorganic semiconductor materials, producing the following colors:

- aluminum gallium arsenide (AlGaAs) - red and infrared

- aluminum gallium phosphide (AlGaP) - green

- aluminum gallium indium phosphide (AlGaInP) - high-brightness orange-red, orange, yellow, and green

- gallium arsenide phosphide (GaAsP) - red, orange-red, orange, and yellow

- gallium phosphide (GaP) - red, yellow and green

- gallium nitride (GaN) - green, pure green (or emerald green), and blue

- indium gallium nitride (InGaN) - near ultraviolet, bluish-green and blue

- silicon carbide (SiC) as substrate - blue

- silicon (Si) as substrate - blue (under development)

- sapphire (Al2O3) as substrate - blue

- zinc selenide (ZnSe) - blue

- diamond (C) - ultraviolet

- aluminum nitride (AlN), aluminum gallium nitride (AlGaN) - near to far ultraviolet

Blue and white LEDs

Commercially viable blue LEDs based on the wide band gap semiconductor gallium nitride and indium gallium nitride were invented by Shuji Nakamura while working in Japan at Nichia Corporation in 1993 and became widely available in the late 1990s. They can be added to existing red and green LEDs to produce white light, though white LEDs today rarely use this principle.

Most "white" LEDs in production today use a 450 nm – 470 nm blue GaN (gallium nitride) LED covered by a yellowish phosphor coating usually made of cerium-doped yttrium aluminum garnet (Ce3+:YAG) crystals which have been powdered and bound in a type of viscous adhesive. The LED chip emits blue light, part of which is efficiently converted to a broad spectrum centered at about 580 nm (yellow) by the Ce3+:YAG. The single crystal form of Ce3+:YAG is actually considered a scintillator rather than a phosphor. Since yellow light stimulates the red and green receptors of the eye, the resulting mix of blue and yellow light gives the appearance of white, the resulting shade often called "lunar white". This approach was developed by Nichia and was used by them from 1996 for manufacturing of white LEDs.

The pale yellow emission of the Ce3+:YAG can be tuned by substituting the cerium with other rare earth elements such as terbium and gadolinium and can even be further adjusted by substituting some or all of the aluminum in the YAG with gallium. Due to the spectral characteristics of the diode, the red and green colors of objects in its blue yellow light are not as vivid as in broad-spectrum light. Manufacturing variations make the LEDs produce light with different color temperatures, from warm yellowish to cold bluish; the LEDs have to be sorted during manufacture by their actual characteristics.

White LEDs can also be made by coating near ultraviolet (NUV) emitting LEDs with a mixture of high efficiency europium based red and blue emitting phosphors plus green emitting copper and aluminum doped zinc sulfide (ZnS:Cu,Al). This is a method analogous to the way fluorescent lamps work. However the ultraviolet light causes photodegradation to the epoxy resin and many other materials used in LED packaging, causing manufacturing challenges and shorter lifetimes. This method is less efficient than the blue LED with YAG:Ce phosphor, as the Stokes shift is larger and more energy is therefore converted to heat, but yields light with better spectral characteristics, which render color better. Due to the higher radiative output of the ultraviolet LEDs than of the blue ones, both approaches offer comparable brightness.

The newest method used to produce white light LEDs uses no phosphors at all and is based on homoepitaxially grown zinc selenide (ZnSe) on a ZnSe substrate which simultaneously emits blue light from its active region and yellow light from the substrate.

A new technique just developed by Michael Bowers, a graduate student at Vanderbilt University in Nashville, involves coating a blue LED with quantum dots that glow white in response to the blue light from the LED. This technique produces a warm, yellowish-white light similar to that produced by incandescent bulbs.

Other colors

Recent color developments include pink and purple. They consist of one or two phosphor layers over a blue LED chip. The first phosphor layer of a pink LED is a yellow glowing one, and the second phosphor layer is either red or orange glowing. Purple LEDs are blue LEDs with an orange glowing phosphor over the chip. Some pink LEDs have run into issues. For example, some are blue LEDs painted with fluorescent paint or fingernail polish that can wear off, and some are white LEDs with a pink phosphor or dye that unfortunately fades after a short time.

Ultraviolet, blue, pure green, white, pink and purple LEDs are relatively expensive compared to the more common reds, oranges, greens, yellows and infrared and are thus less commonly used in commercial applications, however, as of 2006, the "Chernobyl blue" light from blue LEDs has a certain commercial cachet [4] and is used as a styling element in many products such as mobile phones and thus the price has dropped significantly.

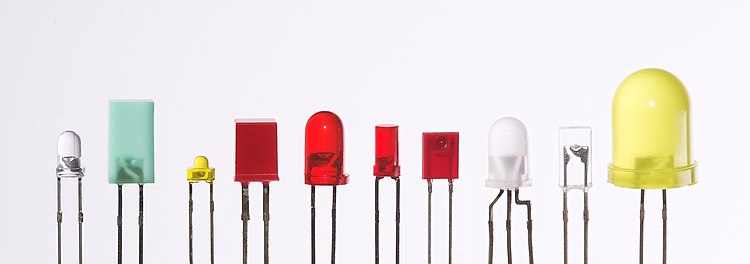

The semiconducting chip is encased in a solid plastic lens, which is much tougher than the glass envelope of a traditional light bulb or tube. The plastic may be colored, but this is only for cosmetic reasons or to improve the contrast ratio; the color of the packaging does not substantially affect the color of the light emitted.

Organic light-emitting diodes (OLEDs)

If the emitting layer material of an LED is an organic compound, it is known as an Organic Light Emitting Diode (OLED). To function as a semiconductor, the organic emitting material must have conjugated pi bonds. The emitting material can be a small organic molecule in a crystalline phase, or a polymer. Polymer materials can be flexible; such LEDs are known as PLEDs or FLEDs.

Compared with regular LEDs, OLEDs are lighter, and polymer LEDs can have the added benefit of being flexible. Some possible future applications of OLEDs could be:

- Inexpensive, flexible displays

- Light sources

- Wall decorations

- Luminous cloth

At present 2006 OLEDs are used in small portable color video displays such as cellphone and digital camera screens, and user interfaces on MP3 players. Large-screen color displays have been demonstrated, but their life expectancy is still far too short (<1,000 Hrs) to be practical.

Operational parameters and efficiency

Most typical LEDs are designed to operate with no more than 30-60 milliwatts of electrical power. Around 1999, commercial LEDs capable of continuous use at one watt of input power were introduced. These LEDs used much larger semiconductor die sizes to handle the large power input. As well, the semiconductor dies were mounted to metal slugs to allow for heat removal from the LED die. In 2002, 5-watt LEDs were available with efficiencies of 18-22 lumens per watt.

In September 2003 a new type of blue LED was demonstrated by the company Cree, Inc. to have 35% efficiency at 20 mA. This produced a commercially packaged white light having 65 lumens per watt at 20 mA, becoming the brightest white LED commercially available at the time. In 2006 they have demonstrated a prototype with a record white LED efficiency of 131 lumens per watt at 20 mA [5].

Today, OLEDs operate at substantially lower efficiency than inorganic (crystalline) LEDs. The best efficiency of an OLED so far is about 10%. These promise to be much cheaper to fabricate than inorganic LEDs, and large arrays of them can be deposited on a screen using simple printing methods to create a color graphic display.

Failure modes

The most common way for LEDs (and diode lasers) to fail is the gradual lowering of light output and loss of efficiency. However, sudden failures can occur as well.

The mechanism of degradation of the active region, where the radiative recombination occurs, involves nucleation and growth of dislocations; this requires a presence of an existing defect in the crystal and is accelerated by heat, high current density, and emitted light. Gallium arsenide and aluminum gallium arsenide are more susceptible to this mechanism than gallium arsenide phosphide, indium gallium arsenide phosphide, and indium phosphide. Due to different properties of the active regions, gallium nitride and indium gallium nitride are virtually insensitive to this kind of defects; however, high current density can cause electromigration of atoms out of the active regions, leading to emergence of dislocations and point defects, acting as nonradiative recombination centers and producing heat instead of light. Ionizing radiation can lead to creation of such defects as well, which leads to issues with radiation hardening of circuits containing LEDs (eg. in optoisolators). Early red LEDs were notable for their short lifetime.

White LEDs often use one or more phosphors. The phosphors tend to degrade with heat and age, losing efficiency and causing changes in the produced light color.

High electrical currents at elevated temperatures can cause diffusion of metal atoms from the electrodes into the active region. Some materials, notably indium tin oxide and silver, are subject to electromigration. In some cases, especially with GaN/InGaN diodes, a barrier metal layer is used to hinder the electromigration effects. Mechanical stresses, high currents, and corrosive environment can lead to formation of whiskers, causing short circuits.

High-power LEDs are susceptible to current crowding, nonhomogenous distribution of the current density over the junction. This may lead to creation of localized hot spots, which poses risk of thermal runaway. Nonhomogenities in the substrate, causing localized loss of thermal conductivity, aggravate the situation; most common ones are voids caused by incomplete soldering, or by electromigration effects and Kirkendall voiding. Thermal runaway is a common cause of LED failures.

Laser diodes may be subject to catastrophic optical damage, when the light output exceeds a critical level and causes melting of the facet.

Some materials of the plastic package tend to yellow when subjected to heat, causing partial absorption (and therefore loss of efficiency) of the affected wavelengths.

Sudden failures are most often caused by thermal stresses. When the epoxy resin used in packaging reaches its glass transition temperature, it starts rapidly expanding, causing mechanical stresses on the semiconductor and the bonded contact, weakening it or even tearing it off. Conversely, very low temperatures can cause cracking of the packaging.

Electrostatic discharge (ESD) may cause immediate failure of the semiconductor junction, a permanent shift of its parameters, or latent damage causing increased rate of degradation. LEDs and lasers grown on sapphire substrate are more susceptible to ESD damage.

Considerations in use

Unlike incandescent light bulbs, which light up regardless of the electrical polarity, LEDs will only light with positive electrical polarity. When the voltage across the p-n junction is in the correct direction, a significant current flows and the device is said to be forward-biased. If the voltage is of the wrong polarity, the device is said to be reverse biased, very little current flows, and no light is emitted. LEDs can be operated on an Alternating current voltage, but they will only light with positive voltage, causing the LED to turn on and off at the frequency of the AC supply.

The correct polarity of an LED can usually be determined as follows:

| sign: | + | − |

| polarity: | positive | negative |

| terminal: | anode | cathode |

| wiring: | red | black |

| leads: | long | short |

| marking: | none | stripe |

| pin: | 1 | 2 |

| PCB: | square | round |

| interior: | small | large |

| exterior: | round | flat |

NOTE: Neither the interior nor exterior method of determing an LED's polarity is 100% accurate. Although the length of the pins (leads) is the most accurate method for determining polarity, even this designation is sometimes reversed.

Because the voltage versus current characteristics of an LED are much like any diode (that is approximately exponential), a small voltage change results in a huge change in current. Added to deviations in the process this means that a voltage source may barely make one LED light while taking another of the same type beyond its maximum ratings and potentially destroying it.

Since the voltage is logarithmically related to the current it can be considered to remain largely constant over the LEDs operating range. Thus the power can be considered to be almost proportional to the current. To try and keep power close to constant across variations in supply and LED characteristics the power supply should be a current source. If high efficiency is not required (e.g. in most indicator applications), an approximation to a current source made by connecting the LED in series with a current limiting resistor to a voltage source is generally used.

Most LEDs have low reverse breakdown voltage ratings, so they will also be damaged by an applied reverse voltage of more than a few volts. Since some manufacturers don't follow the indicator standards above, if possible the data sheet should be consulted before hooking up an LED, or the LED may be tested in series with a resistor on a sufficiently low voltage supply to avoid the reverse breakdown. If it is desired to drive an LED direct from an AC supply of more than the reverse breakdown voltage then it may be protected by placing a diode (or another LED) in inverse parallel.

LEDs can be purchased with built in series resistors. These can save PCB space and are especially useful when building prototypes or populating a PCB in a way other than its designers intended. However the resistor value is set at the time of manufacture, removing one of the key methods of setting the LEDs intensity. To increase efficiency (or to allow intensity control without the complexity of a DAC), the power may be applied periodically or intermittently; so long as the flicker rate is greater than the human flicker fusion threshold, the LED will appear to be continuously lit.

Provided there is sufficient voltage available, multiple LEDs can be connected in series with a single current limiting resistor. Parallel operation is generally problematic. The LEDs have to be of the same type in order to have a similar forward voltage. Even then, variations in the manufacturing process can make the odds of satisfactory operation low. For more information see Nichia Application Note.

Bicolor LED units contain two diodes, one in each direction (that is, two diodes in inverse parallel) and each a different color (typically red and green), allowing two-color operation or a range of apparent colors to be created by altering the percentage of time the voltage is in each polarity. Other LED units contain two or more diodes (of different colors) arranged in either a common anode or common cathode configuration. These can be driven to different colors without reversing the polarity.

LED units may have an integrated multivibrator circuit that makes the LED flash.

Advantages of using LEDs

- LEDs can emit light of an intended color without the use of color filters that traditional lighting methods require. This is more efficient and can lower initial costs.

- The solid package of an LED can be designed to focus its light. Incandescent and fluorescent sources often require an external reflector to collect light and direct it in a useable manner.

- LEDs are built inside solid cases that protect them, unlike incandescent and discharge sources, making them extremely durable.

- LEDs have an extremely long life span: typically ten years, twice as long as the best fluorescent bulbs and twenty times longer than the best incandescent bulbs. (Incandescent bulbs can also be made to last an extremely long time by running at lower than normal voltage, but only at a huge cost in efficiency; LEDs have a long life when operated at their rated power.)

- Further, LEDs fail by dimming over time, rather than the abrupt burn-out of incandescent bulbs.

- LEDs give off much less heat than incandescent light bulbs with similar light output.

- LEDs light up very quickly. An illumination LED will achieve full brightness in approximately 0.01 seconds, 10 times faster than an incandescent light bulb (0.1 second), and many times faster than a compact fluorescent lamp, which starts to come on after 0.5 seconds or 1 second, but does not achieve full brightness for 30 seconds or more. A typical red indicator LED will achieve full brightness in microseconds, or possibly less if it's used for communication devices.

Disadvantages of using LEDs

- LEDs are currently more expensive, in lumens per dollar, than more conventional lighting technologies. The additional expense partially stems from the relatively low lumen output, and the drive circuitry and power supplies needed.

- LED performance largely depends on the ambient temperature of the operating environment. "Driving" an LED "hard" in high ambient temperatures may result in overheating of the LED package, eventually leading to device failure. Adequate heat-sinking is required to maintain long life. This is especially important when considering automotive/military applications where the device must operate over a large range of temperatures, with government-regulated output.

LED applications

List of LED applications

Some of these applications are further elaborated upon in the following text.

LEDs are used as informative indicators in various types of embedded systems:

- Status indicators

- Traffic Lights and Signals

- continuity indicators

- Light bars on emergency vehicles.

- Thin, lightweight message displays at airports and railway stations and as destination displays for trains, buses, trams and ferries.

- Red or yellow LEDs are used in indicator and alphanumeric displays in environments where night vision must be retained: aircraft cockpits, submarine and ship bridges, astronomy observatories, and in the field, e.g. night time animal watching and military field use.

- Red, yellow, green, and blue LEDs can be used for Model Railroading applications

to transmit digital information:

- Remote controls for TVs, VCRs, etc, using infrared LEDs.

- In optical fiber communications.

- In dot matrix arrangements for displaying messages.

- In traffic signals, LED clusters are replacing colored incandescent bulbs.

- Movement sensors, for example, in optical computer mouse

Illumination applications

LEDs used as a replacement for incandescent light bulbs and fluorescent lamps are known as solid-state lighting (SSL) - packaged as a cluster of white LEDs grouped together to form a light source (pictured). LEDs are moderately efficient: the average commercial SSL currently outputs 32 lumens per watt (lm/W), and new technologies promise to deliver up to 80 lm/W. The long lifetime of LEDs make SSL very attractive. They are also more mechanically robust than incandescent light bulbs and fluorescent tubes. Currently, solid state lighting is not readily available for household use, requires power source conversion in household applications, and is relatively expensive, although costs are decreasing. LED flashlights however already have become widely available. Recently a number of manufacturers have started marketing ultra-compact LCD video projectors that use high-powered white LEDS for the light source.

Incandescent bulbs are much less expensive but also less efficient, generating from about 16 lm/W for a domestic tungsten bulb to 22 lm/W for a halogen bulb. Fluorescent tubes are more efficient, providing 50 to 100 lm/W for domestic tubes (average 60 lm/W), but are bulky and fragile and require starter or ballast circuits that sometimes buzz audibly. Compact fluorescent lamps, which include a quiet integrated ballast, are relatively robust and efficient, fit in standard light bulb sockets, and are currently the best choice for efficient household lighting.

Proponents of LEDs expect that technological advances will reduce costs such that SSL can be introduced into most homes by 2020. However, they are still not commercially viable for general lighting applications, and so LEDs are found today in illumination applications where their special characteristics provide a distinct advantage. This can be seen in the widespread use of LEDs in traffic signals and indicator lamps for trucks and automobiles.

Due to their monochromatic nature, LED lights have great power advantages over white lights when a specific color is required. Unlike traditional white lights, the LED does not need a coating or diffuser that can absorb much of the emitted light. LED lights are inherently colored, and are available in a wide range of colors. One of the most recently introduced colors is the emerald green (bluish green, about 500 nm) that meets the legal requirements for traffic signals and navigation lights.

There are applications that specifically require light without any blue component. Examples are photographic darkroom safe lights, illumination in laboratories where certain photo-sensitive chemicals are used, and situations where dark adaptation (night vision) must be preserved, such as cockpit and bridge illumination, observatories, etc. Yellow LED lights are a good choice to meet these special requirements because the human eye is more sensitive to yellow light (about 500 lm/watt emitted) than that emitted by the other LEDs.

LED display panels

There are two types of LED panels: conventional, using discrete LEDs, and Surface Mounted Device (SMD) panels. Most outdoor screens and some indoor screens are built around discrete LEDs, also known as individually mounted LEDs. A cluster of red, green, and blue diodes is driven together to form a full-color pixel, usually square in shape. These pixels are spaced evenly apart and are measured from center to center for absolute pixel resolution. The largest LED display in the world is over 1,500 feet long and is located in Las Vegas, Nevada covering the Fremont Street Experience.

Most indoor screens on the market are built using SMD technology — a trend that is now extending to the outdoor market. An SMD pixel consists of red, green, and blue diodes mounted on a chipset, which is then mounted on the driver PC board. The individual diodes are smaller than a pinhead and are set very close together. The difference is that minimum viewing distance is reduced by 25% from the discrete diode screen with the same resolution.

Indoor use generally requires a screen that is based on SMD technology and has a minimum brightness of 600 candelas per square meter (unofficially called nits). This will usually be more than sufficient for corporate and retail applications, but under high ambient-brightness conditions, higher brightness may be required for visibility. Fashion and auto shows are two examples of high-brightness stage lighting that may require higher LED brightness. Conversely, when a screen may appear in a shot on a television show, the requirement will often be for lower brightness levels with lower color temperatures (common displays have a white point of 6500-9000K, which is much bluer than the common lighting on a television production set).

For outdoor use, at least 2,000 nits are required for most situations, whereas higher brightness types of up to 5,000 nits cope even better with direct sunlight on the screen. Until recently, only discrete diode screens could achieve that brightness level. (The brightness of LED panels can be reduced from the designed maximum, if required.)

Suitable locations for large display panels are identified by factors such as line of sight, local authority planning requirements (if the installation is to become semi-permanent), vehicular access (trucks carrying the screen, truck-mounted screens, or cranes), cable runs for power and video (accounting for both distance and health and safety requirements), power, suitability of the ground for the location of the screen (check to make sure there are no pipes, shallow drains, caves, or tunnels that may not be able to support heavy loads), and overhead obstructions.

Multi-Touch Sensing

Since LEDs share some basic physical properties with photodiodes, which also use p-n junctions with band gap energies in the visible light wavelengths, they can also be used for photo detection. These properties have been known for some time, but more recently so-called bidirectional LED matrices have been proposed as a method of touch-sensing. In 2003, Dietz, Yerazunis, and Leigh published a paper[6] describing the use of LEDs as cheap sensor devices.

In this usage, various LEDs in the matrix are quickly switched on and off. LEDs that are on shine light onto a user's fingers or a stylus. LEDs that are off function as photodiodes to detect reflected light from the fingers or stylus. The voltage thus induced in the reverse-biased LEDs can then be read by a microprocessor, which interprets the voltage peaks and then uses them elsewhere. The website of Jeff Han features a video[7] demonstrating one such implementation of an LED matrix multi-touch sensor.

ความเห็น (0)

ไม่มีความเห็น